The plastic pollution crisis is one of the most pressing environmental issues of our time, and it has inspired individuals, organizations, and businesses to come up with innovative solutions for dealing with the plastic waste that is overwhelming our ecosystem.

Companies around the world are developing ways to make roads out of plastic, volunteer groups are weaving sleeping mats from used plastic bags, and some inventive minds are even designing homes made from recycled plastic.

Another company has joined the war against single-use plastics and has developed a method for turning used plastic bags, bottles, and other items into lumber.

Goodwood Plastic Products Ltd.

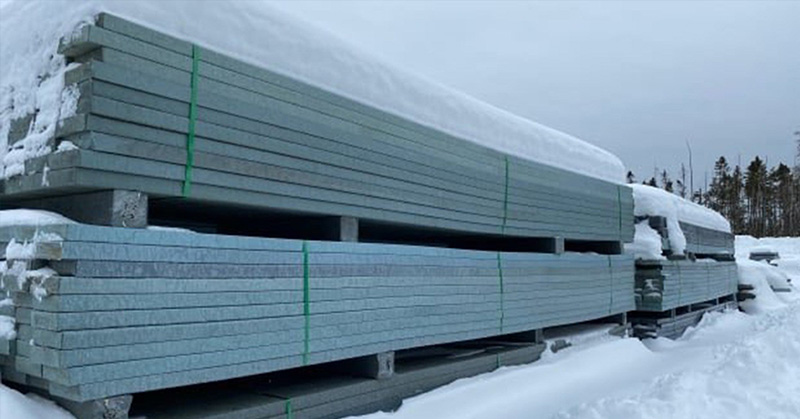

Based in Halifax, Nova Scotia, Canada Goodwood Plastic Products Ltd. is now taking about 80% of municipal plastics and manufacturing them into synthetic lumber, wharf timbers, guardrail posts and agricultural posts [1].

The company offers complete industrial waste management services, from collection to recycling, will help businesses adopt sustainable recycling practices, and focuses on disposing of all waste while minimizing their environmental impact [2].

Goodwood’s vice president, Mike Chassie, has been a long-time environmental advocate and is proud that they have been able to find a “home-grown” solution to their local plastic problem. His company’s product has now been used by other businesses to build outdoor furniture like park benches and picnic tables [1].

According to Chassie, the product can be used in the exact same way as wood.

“You can saw it the same, you can drill it the same. You can use screws, nails, bolts (to fasten it). You can glue it.” [3]

How Do They Turn Plastic Into Lumber?

Once bales of plastic collected throughout the municipality and brought to the Goodwood plant, glass, aluminum, and metals have to be removed. The plastic is then shredded in a machine called the granulator, then pushed through a primary extruder which turns it into rigid, tube-shaped plastic pieces [3].

These pieces are then sheared into small chunks and eventually turned into plastic chips, which can then be melted down and formed into boards or posts. Each product is made up of about 75 percent plastic bags and other film plastics, and the remaining 25 percent comes from plastic jugs [3].

Business is Booming

According to Chassie, the product is incredibly durable yet flexible, and will last much longer than traditional materials, which makes it the ideal product for “anyone who wants to buy plastic lumber and wants it to last forever”.

“I have 500 phone numbers of people I am supposed to call back when I have lumber ready. They want it for anything outdoors. If you’ve building a shed and you need a bottom, your shed is going to sit on the ground, it’s the perfect product, it will never rot out.”

– Chassie said to The Chronical Herald

Currently, the company is working with Lake City, a not-for-profit based in Dartmouth that provides employment for people with mental illness.

A Proving Ground

Recently, Goodwood partnered with a local Sobeys and created one of the first parking lots in Canada made almost completely out of recycled plastics. The plastic was used in the lot’s asphalt mixture, which diverted more than six million plastic shopping bags from the landfill [4].

Andrew Philopoulos, manager of Halifax’s solid waste division, said that after China stopped accepting recycled plastic in 2017, there was a 90 to 95 percent backlog of the material that accumulated. He believes that Goodwood has solved this problem, at least in the short-term [3].

Read: Coca-Cola is World’s Largest Plastic Polluter for Second Year straight

Government Regulations Affecting Business

Having previous experience with government regulations impacting his business, Chassie is concerned that that proposed plastic bag-ban by the Halifax Regional Municipality could threaten what he has created.

“The plastic bag ban is something that is created by individuals who don’t understand the industry and don’t understand a quality resource that creates jobs,” Chassie said. “Plastic bags are not a problem. People are a problem. If you fill your plastic bag with garbage and then throw it into the landfill, then its landfill. But if you collect it, sort it and make sure it goes to a recycling facility …” [4]

He argues that if a single-use plastic can be turned into a board, it is no longer single-use. Having experience with government interference in other industries like tires and hardwood, he fully expects they will interfere with this as well [4].

I am trying to build my business plan so I can operate whatever they pull,” he said. “I don’t think they are ever going to get rid of all the single-use plastic bags. We will source what we need from out of province, out of country if we have to.” [4]

Resources, Not Waste

Chassie is aware that there are other cities, municipalities, and jurisdictions all over the world who are facing similar plastic problems as they are in Halifax, and he plans to make his company a part of the solution.

“We can take this business — the knowledge and our skills — and we can export it and take it to other places. Post-consumer plastic is not going away, so we need to continue to find ways to give it a new life so it becomes a resource, instead of a waste.” [3]

As his business continues to grow, pretty soon you may be able to sit on a bench that was once the shopping bag you threw in your recycling bin. With more and more companies like Goodwood coming up with innovative solutions to the global plastic problem, we will hopefully begin to a shift towards a cleaner, more plastic-free environment all over the world.

Keep Reading: People still want plastic bottles, says Coca-Cola

- https://www.cbc.ca/news/canada/nova-scotia/goodwood-plastics-halifax-municipality-plastics-recycling-1.5421166

- https://goodwoodplastic.com/

- https://www.thechronicleherald.ca/business/colchester-countys-plastic-lumber-maker-thrives-on-recycled-grocery-bags-282600/

- https://www.cbc.ca/news/canada/nova-scotia/sobeys-plastic-parking-lot-timberlea-nova-scotia-1.5380857