Approximately six million people break a bone every year in the United States [1]. There’s a good chance you know someone personally who has broken a bone – maybe that person is you.

Regardless of whether or not it’s a simple stress fracture or a full-blown break, breaking a bone is painful, and the recovery process is uncomfortable, long, and inconvenient. In many cases, you end up having to wear an itchy, cumbersome cast and are forced to alter your daily activities to accommodate it.

Thankfully, there are some engineering students in Chicago who believe that recovering from a broken bone does not have to be worse than the break itself.

How to Heal from a Break

In order for your body to heal from a bone break, it requires three things: Good blood supply after the injury, adequate stabilization, and enough new tissue formation [2].

In some cases, such as after a stress fracture, a simple splint may be all that is required. However a more severe break a full cast is usually what is needed in order to sufficiently stabilize the bone to allow it to heal [3].

Casts are typically made from either plaster or fiberglass [3]. Fiberglass is more lightweight, durable, and porous, allowing more airflow into the cast, however, plaster is more easily shaped than fiberglass and is much less expensive [3].

In either case, they are both cumbersome, can often get quite itchy, and require a specialized saw to be removed [3].

Applying a Plaster or Fibreglass Cast

There are several steps to applying a cast. First, you have to place a “stockinette” on the skin where the cast begins and ends to protect it from the casting material. Then, a soft cotton passing material is rolled on to provide further protection and padding to the skin, as well as elastic pressure to the break to help with healing. Finally, the plaster or fiberglass material is rolled on in wet sheets. It can take up to 24-48 hours for the cast to completely harden and set [4].

Once the cast is on, you have to be very careful with it. You have to keep it cool and dry, to avoid warping the cast and to keep your skin from getting wet underneath it. This, of course, means no swimming, and you will have to use a plastic bag or a special cast cover when you shower [3]. Fiberglass casts are more water-resistant than plaster, but not completely waterproof. However, some fiberglass casts can be waterproofed, a costlier option, but something to discuss with your doctor if you feel you’ll need it.

A New Type of Cast

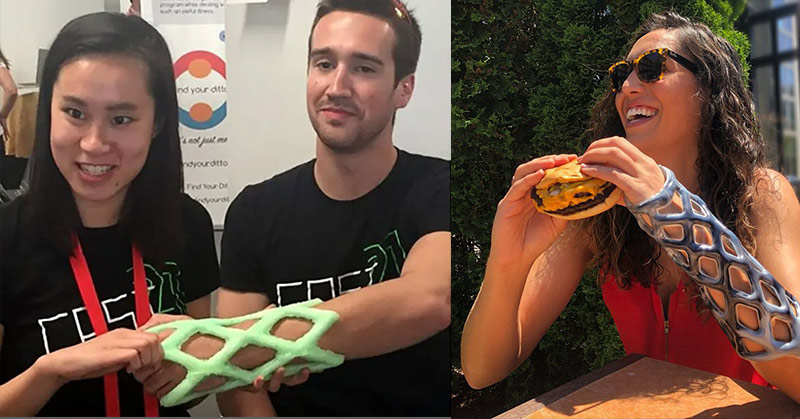

Cast21 is a Chicago-based startup pioneered by three students from the University of Illinois [5]. Jason Troutner, biomedical design engineer Ashley Moy, and electrical engineer Justin Brooks believe that orthopedic casting has been long overdue for an upgrade, and have created a solution to improve the treatment process for both the doctor and the patient [6].

This new cast is lightweight, breathable, and water-proof, so it can be worn in the shower and in the pool, and comes in a variety of fun colors [7].

The process of putting the cast on can take less than ten minutes. First, the doctor will measure the patient’s arm and select the appropriately-sized cast. Then he or she will put it on the patient’s limb and fill it with a mix of resins. These resins only take a few minutes to harden into a malleable gel. The doctor then molds it to the patient’s arm and waits another five minutes for the cast to harden [5].

What Makes this Cast So Much Better?

Traditional plaster or fiberglass casts are considered by many physicians to be unhygienic. Patients are unable to clean underneath them, which can cause sores and infections [7].

Since this new device is waterproof and much more breathable, patients can properly wash the affected limb without damaging the cast or slowing down the healing process [7].

Cast21 is better for physicians and medical providers because it is moldable, provides visibility to the skin underneath, does not require water, heat, or additional equipment to apply, and does not require a saw to be removed. It saves space because there is less equipment that needs to be stored and allows doctors to see more patients because of time savings [6].

Cast21 is better for patients because it is waterproof, lightweight and comfortable, allowing you to go about your daily tasks with much greater ease [6].

“We have this radical notion that you can enjoy your healing experience. You don’t need to be restrained from daily activities,” says Cast21’s vice president of engineering, Vanessa Hogg [7].

What’s more, since the cast does not need any electricity or water to apply, it is very portable. This gives it the potential to be used in the military, for at-home first aid, and even on camping trips [5].

Next Steps

This new cast is still a work in progress. At this time, the company only has a model of the cast in medium forearm size. They are hoping to expand their sizing and to create a design for legs as well [7].

The product does not yet have a price either, but Cast21’s goal is to make it as accessible as possible.

“We don’t want this to be a luxury product. We are still conducting research in price sensitivity, and the final cost to the patients will be depending on their insurance and doctor.” [7]

The team is currently working with physicians to get their feedback and increase doctors’ comfortability with using the product in a variety of cases, including after surgery is provided [7].

While Cast21 may still be in developmental stages, this product could have a widespread positive impact on both physicians and patients alike.

- https://u.osu.edu/productdesigngroup3/sample-page/

- https://u.osu.edu/productdesigngroup3/sample-page/

- https://my.clevelandclinic.org/health/drugs/15211-casts–splints

- https://www.emedicinehealth.com/cast_care/article_em.htm#how_are_casts_applied

- https://www.distractify.com/p/cast21-plaster-cast

- https://www.cast21.com/

- https://www.dailymail.co.uk/health/article-7705717/The-end-plaster-cast-Start-creates-waterproof-mesh-like-alternative.html