Scientists have created the world’s first 3D-printed heart. Heart disease is the leading cause of death in the United States. In fact, every year it takes approximately 655 thousand lives. That means that one in every four deaths in the US are a result of heart disease [1].

For end-stage heart disease, the only option is heart transplant surgery. Unfortunately, there are about three thousand people on the waiting list for a heart on any given day, and only about two thousand available hearts every year [2].

This 3D-printed heart could solve the organ shortage, and save thousands of lives.

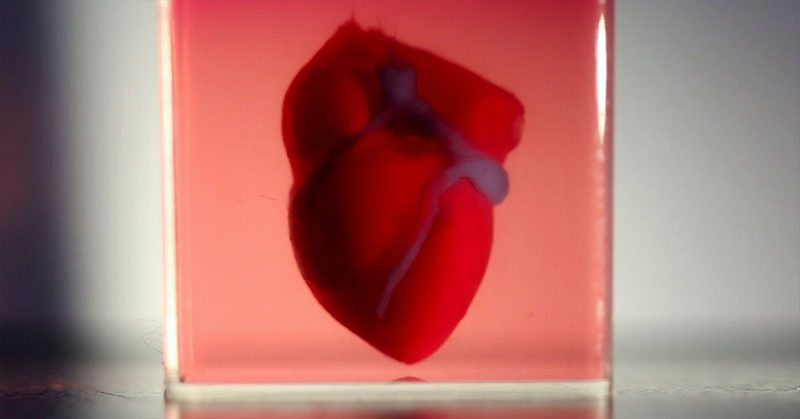

The World’s First 3D-Printed Heart

Researchers from Tel Aviv University have created a 3D-printed heart using a patient’s own cells and biological materials. This is the first time anyone has engineered a heart with actual blood vessels using a 3D printer.

Professor Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology, Department of Materials Science and Engineering, Center for Nanoscience and Nanotechnology, and Sagol Center for Regenerative Biotechnology, led the study.

“This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles, and chambers,” he said [3].

According to Professor Dvir, others have created 3D-printed hearts in the past, but these were just the structure of the organ. They did not have cells or blood vessels. He and his team, however, made this heart from human cells and patient-specific biological materials.

“In our process these materials serve as the bioinks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models,” he explained [3].

Read: Rescuers Print 3-D Shell For Tortoise Who Had His Burnt Off In A Fire

How Did They Make It?

To make the 3D-printed heart, the researchers took a biopsy of fatty tissue from the patients. They then separated the cellular and a-cellular tissues, and they reprogrammed the cells to become pluripotent stem cells. Pluripotent means that the cells are able to give rise to several different cell types.

While that was happening, the researchers processed the extracellular matrix (ECM) into a personalized hydrogel. (The ECM is a 3D network of macromolecules such as collagen and glycoproteins). They used this hydrogel as the “ink”.

Once the cells had differentiated into either cardiac (heart), or endothelial (lining of the heart and blood vessels) cells, the team mixed them with the hydrogel. In doing so, they managed to create patient-specific, immune-compatible cardiac patches with blood vessels. Thus, they were able to make an entire heart [4].

Using native, patient-specific cells is incredibly important when making a 3D-printed heart. According to professor Dvir, this is crucial in eliminating the risk that the patient’s body will reject the implant.

“Ideally, the biomaterial should possess the same biochemical, mechanical and topographical properties of the patient’s own tissues,” he explained. “Here, we can report a simple approach to 3D-printed thick, vascularized and perfusable cardiac tissues that completely match the immunological, cellular, biochemical and anatomical properties of the patient.” [3]

Next Steps

Currently, the 3D-printed heart is very small- only about the size of a rabbit’s heart. Professor Dvir says, however, that creating a larger human heart requires the same technology and process. He is confident that their research will change the future of organ donation.

“Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future,” he said [3].

For now, he says, they need to develop the 3D-printed heart further. The team’s next step will be to “teach” these printed hearts how to function like a real human heart. Dvir says that currently, the cells can contract but they need to work together in order to form the ability to pump.

“Maybe, in 10 years, there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely,” he said [5].

If this is the case, Dvir and his team may have found the solution to organ shortages around the world.

Keep Reading: Doctors Made A 3D Print Of An Ultrasound For A Blind Expecting Mama

Sources

- https://www.cdc.gov/heartdisease/facts.htm#:~:text=Heart%20disease%20is%20the%20leading,1%20in%20every%204%20deaths.

- https://medicine.umich.edu/dept/cardiac-surgery/patient-information/adult-cardiac-surgery/adult-conditions-treatments/heart-transplant

- https://www.sciencedaily.com/releases/2019/04/190415102242.htm

- https://onlinelibrary.wiley.com/doi/full/10.1002/advs.201900344

- https://www.nbcnews.com/mach/science/israeli-scientists-create-world-s-first-3d-printed-heart-using-ncna996031